If you were to take an end-suction pump, stand it on end, and fashion a suction elbow to the bottom, you would have created a crude vertical inline pump. In fact, many manufacturers share hydraulic designs between end-suction and vertical inline products.

Vertical inline pumps can be considered for any application for which an end-suction pump is considered acceptable as they offer similar longevity. While typically a little more expensive than end-suction pumps due to slightly higher motor costs, vertical inline’s have the added benefit of requiring very little floor space, which explains their popularity in commercial construction where square footage is at a premium.

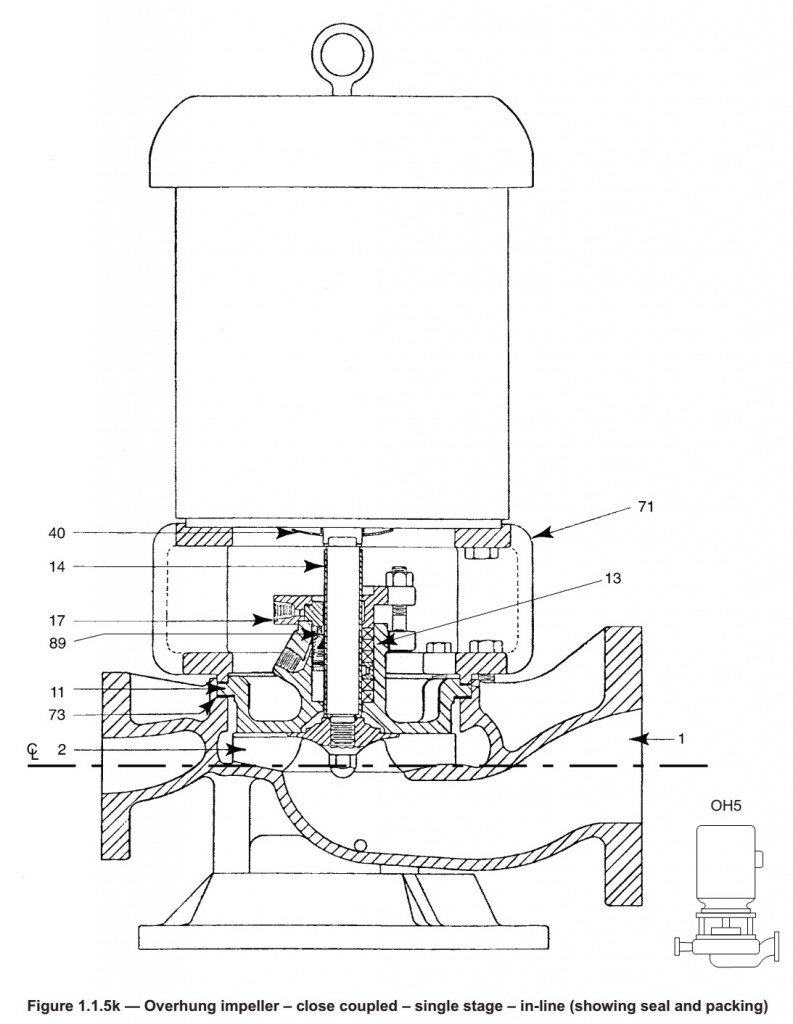

Close-Coupled Vertical Inline Pumps

Close-coupled vertical inline pumps are commonly used for ratings up to 50 HP. The close-coupled design incorporates an impeller mounted directly on the end of the motor shaft, and a pump casing that bolts directly to the face of the motor.

Close-couped vertical inline pumps (VIL) are the most affordable type of VIL, and several manufacturers are able to ship standard VILs in as few as two or three business days.

Vertical inline pumps – especially of the close-coupled variety are popular in the commercial building trades: HVAC, plumbing, and fire protection. They are used sparingly in other applications, primarily due to a lack of familiarity rather than any technical challenges or shortcomings.

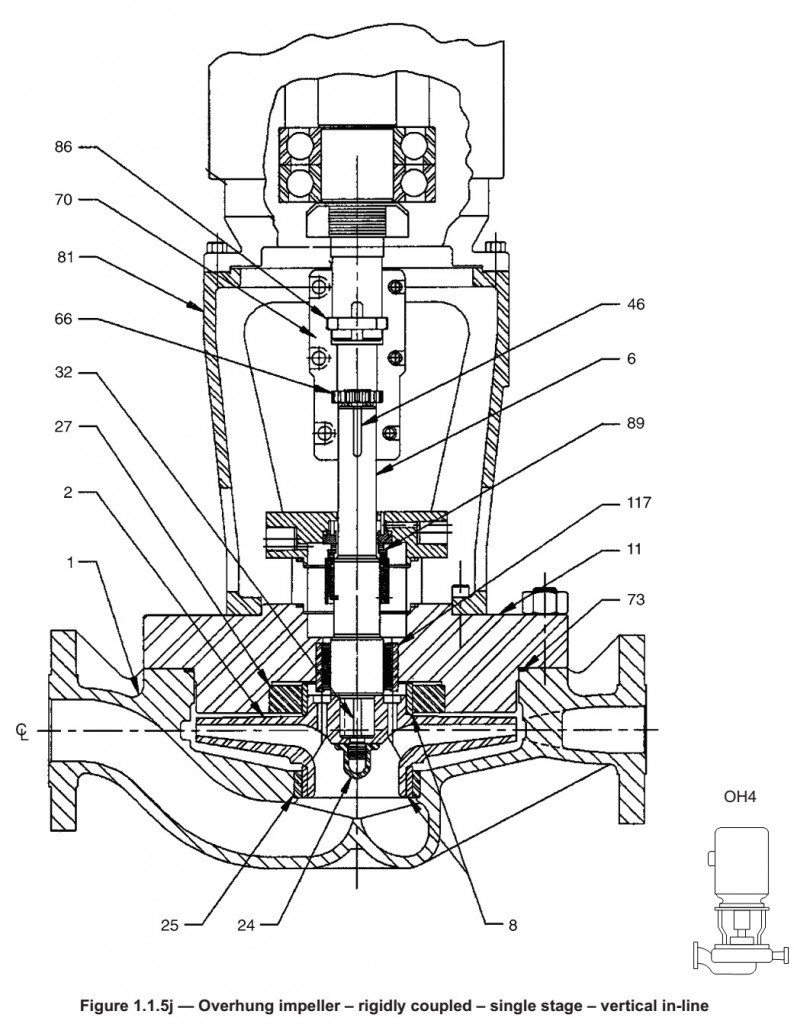

Rigid-Coupled Vertical Inline Pumps

Rigid-coupled VILs have a two-shaft design: a motor shaft and pump shaft coupled together with a rigid aluminum or steel coupling. The result is that the pump shaft is rigidly fixed to the motor shaft, and the motor bearings carry all of the thrust loads generated by the impeller.

Rigid-coupled VILs are often chosen for applications for which a suitable motor is not available for a close-coupled design. Close-coupled units are typically built with a standard motor with an added “c-face” – a plate mounted on the front of the motor specifically designed to make the motor suitable for close-coupling. Rigid-coupeld units, on the other hand, are typically built with a true vertical solid shaft motor.

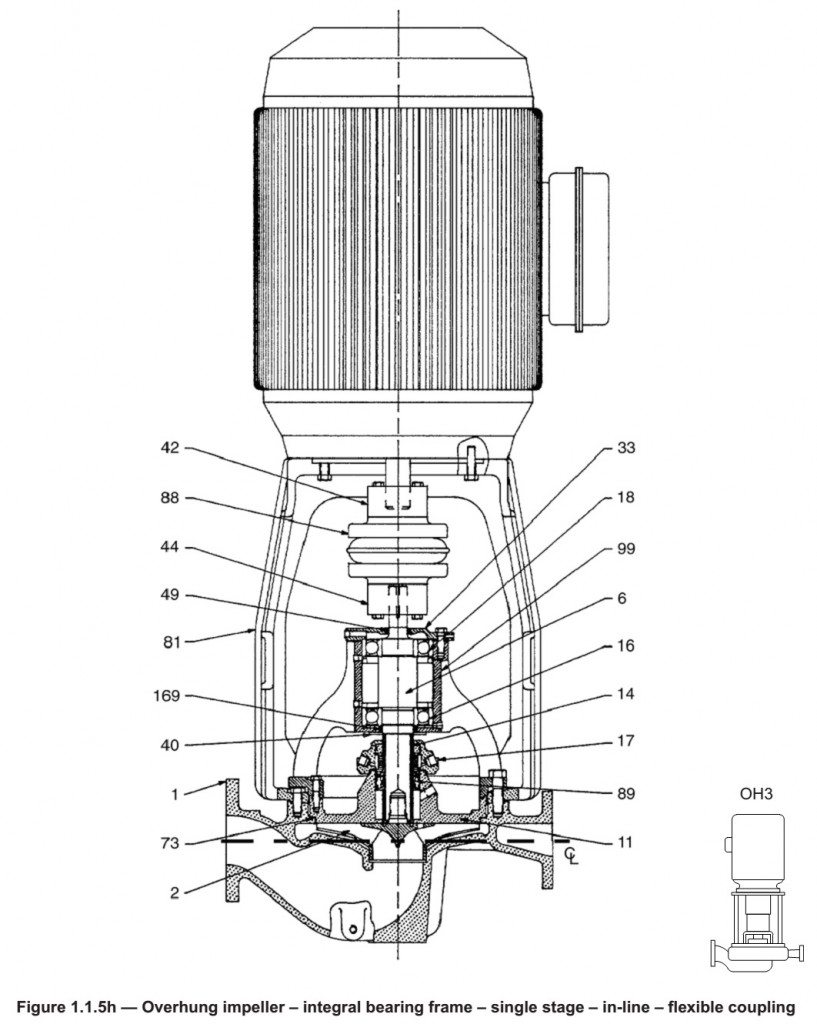

Flex-Coupled Vertical Inline Pumps

Flex-coupled VILs are not as common as their close-coupled and rigid-coupled counterparts. This type of VIL is only offered by a handful of manufacturers. Both close-coupled and rigid-coupled VILs depend on the motor bearings to handle the thrust loads created and imposed by the spinning impeller. Not so in a flex-coupled VIL which include a thrust bearing assembly built into the pump itself. As a result, the coupling between the pump and motor can be made with a flexible coupling, and the motor does not need to be capable of handling any downthrust beyond the weight of the coupling.