A centrifugal pump is a machine that uses rotation to impart velocity to a liquid and then converts that velocity into flow.

Let’s break that definition down into its components so that we can consider each one in turn:

- A centrifugal pump is a machine.

- A centrifugal pump uses rotation to impart velocity to a liquid.

- A centrifugal pump converts velocity into flow.

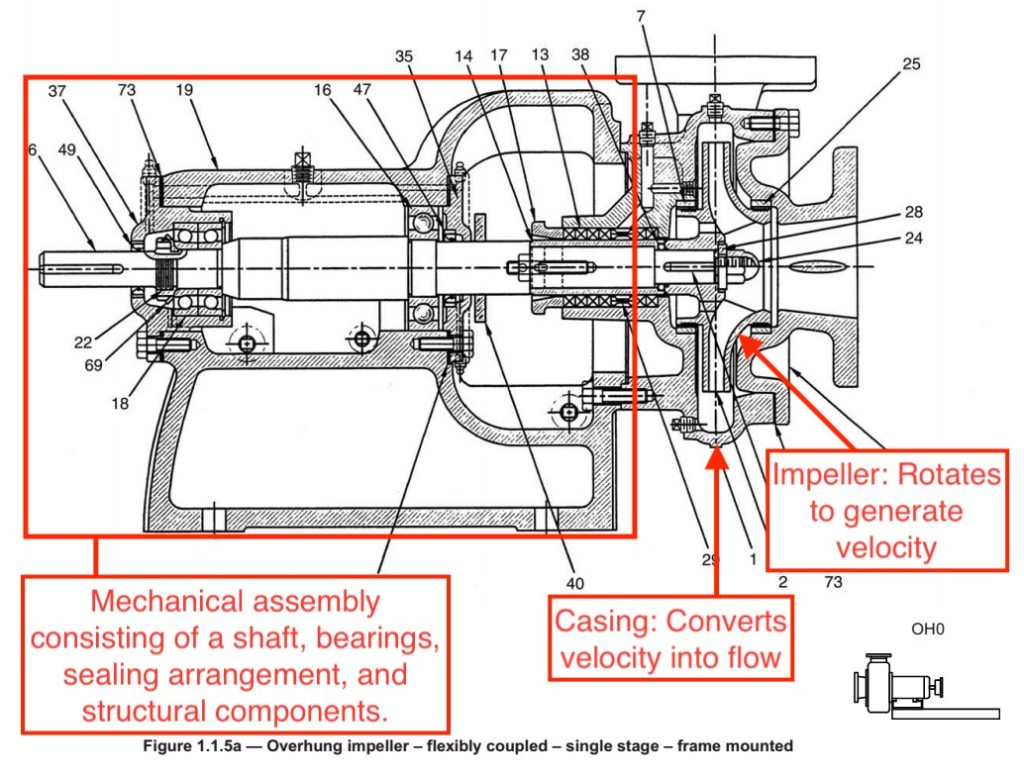

“A centrifugal pump is a machine.” Every centrifugal pump includes an assembly of mechanical components that make operation of the pump possible. This mechanical assembly includes the pump shaft mounted on bearings, the sealing mechanism that keeps the pump from leaking excessively, structural components designed to handle the stresses and loads imposed on the pump during operation, and wear surfaces that allow the pump to be repaired and returned to its original specifications.

“A centrifugal pump uses rotation to impart velocity to a liquid.” Every centrifugal pump includes an impeller. The impeller is the hydraulic component that rotates to impart velocity to the pumped liquid.

“A centrifugal pump converts velocity into flow.” Every centrifugal pump includes a casing. The casing is the hydraulic component that captures the velocity imparted by the impeller and directs the pumped liquid to the pump discharge point.

At the most fundamental level, a centrifugal pump consists of just these three components:

- An impeller that rotates and imparts velocity to a liquid.

- A casing that captures the velocity generated by the impeller and transforms that velocity into a stable flow.

- An assembly of mechanical components that makes it possible for the impeller to be rotated within the pump casing.

Centrifugal Pump Impellers

The impeller of a centrifugal pump is rotated rapidly to impart velocity to a pumped liquid.

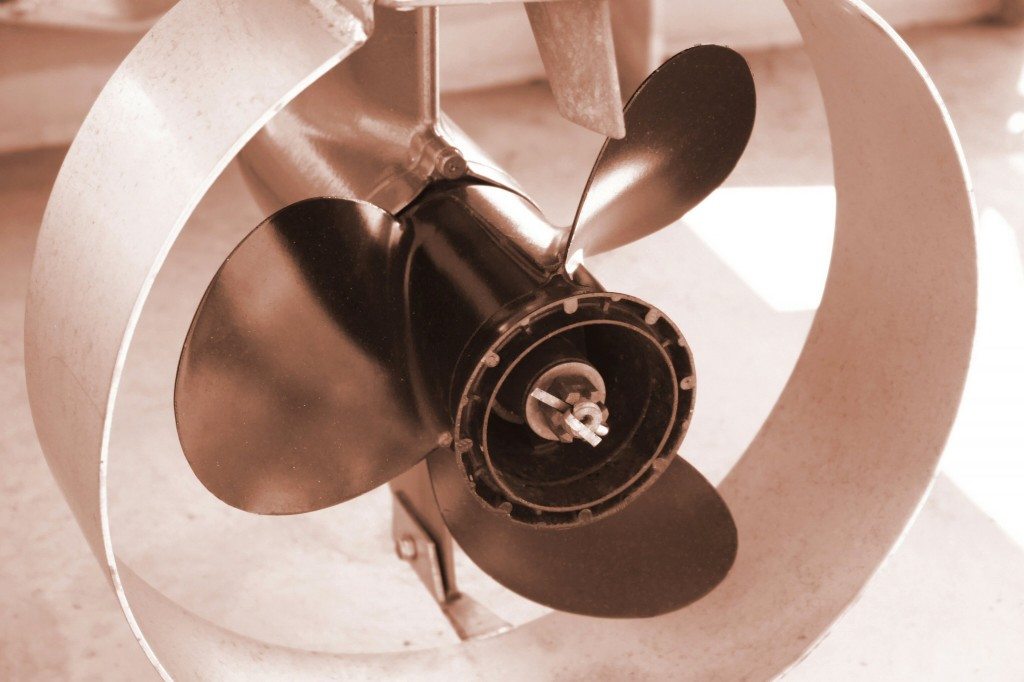

If you’ve never seen a pump impeller before, visualize a boat propeller.

When a boat propeller is rotated it imparts velocity to the liquid around it. As the liquid moves, that velocity forces the propeller to move forward in the water.

Now imagine what would happen if the boat were anchored in place, firmly enough to prevent the boat from moving. Next imagine that the velocity generated by the boat propeller were contained and controlled so that a stream of water was created that you could direct where you pleased.

In effect, what we’ve just described is a centrifugal pump – in fact, an axial-flow pump resembles what we’ve just described to a significant degree.

In a centrifugal pump you have an impeller rotating rapidly and imparting velocity to the liquid in the pump just as a boat propeller imparts velocity to the water in a lake. The casing is the part of the arrangement that takes that velocity, contains it, controls it, and sends it along in a useful direction.

Every impeller has 1 or more vanes that extend from the center, or hub, of the impeller out towards the outer diameter. As the impeller turns, centrifugal force causes the liquid to move rapidly from the center of the impeller, along the vanes, and then exit the impeller at the outermost diameter. The result is that the pumped liquid exits the perimeter of the impeller at a very high velocity.

There are many different types of centrifugal pump impellers. The most common types of pump impellers are discussed in our article Fundamental Pump Components: Volutes, Casings, and Impellers.

Centrifugal Pump Casings

The centrifugal pump casing is the component of the pump that converts all of the velocity created by the rotating impeller into a controlled and stable flow and directs it out of the pump through the discharge point.

The most common type of casing is called a volute and it looks similar to a snail shell.

The impeller is placed within the volute. However, as you may have noticed in the image above, the impeller is not typically centered in the volute.

Instead, the impeller is positioned so that the outer diameter of the impeller is closest to the volute at the point just past the discharge. This point where the impeller is closest to the volute is called the cutwater.

Beginning from the cutwater, as we move around the impeller, the distance between the volute and impeller gradually increases until we reach the discharge point. This steady expansion of the area around the impeller means that pressure will build moving from the smallest clearance to the greatest and the increasing pressure will push the liquid out of the discharge point.

We’ve just touched briefly on the topic of pump casing design in this article. Additional information about the most common types of pump casings can be found in our article Fundamental Pump Components: Volutes, Casings, and Impellers.

Centrifugal Pumping Units

Centrifugal pumps aren’t much use on their own. They need to be combined with other equipment to be useful. The combination of equipment that renders a centrifugal pump operable is referred to as a pumping unit.

At a minimum, a centrifugal pumping unit includes at least two components: a pump and a driver.

In the majority of cases, the driver in a centrifugal pumping system is an electric motor. However, that isn’t always the case. Pumps can also be driven by other drivers such as natural gas engines or even steam turbines.

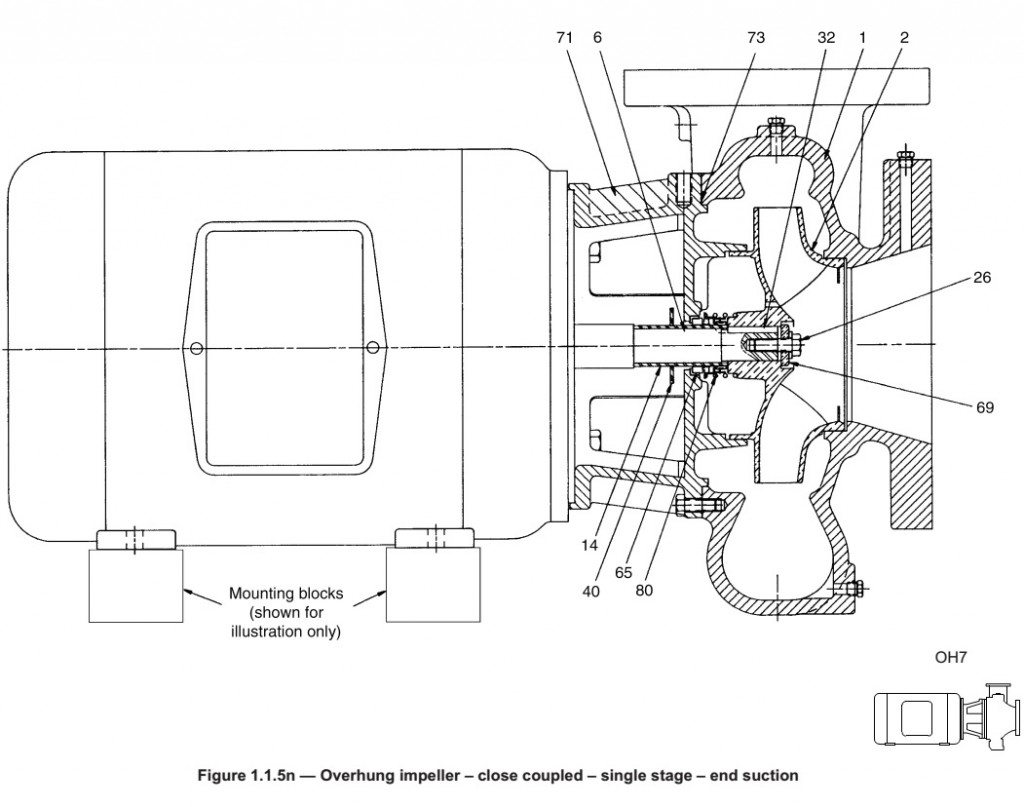

The most common pumping unit combines a centrifugal pump driven by an electric motor.

The image above is of a close-coupled end-suction pump. This is the simplest and most common type of centrifugal pumping unit. In this type of pumping unit the impeller actually mounts on the end of the motor shaft and the pump casing mounts right onto the face of the motor. With a close-coupled pumping unit, the motor bearings and shaft comprise the majority of the mechanical portion of the pump.

Another common pump design is the frame-mounted end-suction pump. With a frame-mounted end-suction pump, the pump does include a complete mechanical assembly and is coupled to a driver, both of which are mounted on a shared baseplate.

This is far from an exhaustive list of possible pumping unit configurations. In the article on common pump designs we’ll dive into other common pumping unit configurations. For the time being, the point to take away is that a pumping unit consists of a centrifugal pump and a driver, such as an electric motor, and may also include additional components such as baseplates and couplings depending on the design of the pump.

Summary

A centrifugal pump is a machine that uses rotation to impart velocity to a liquid and then converts that velocity into flow.

Every centrifugal pump consists of an impeller, a casing, and an assembly of mechanical components that make it possible for the impeller to rotate within the casing. The impeller rotates rapidly imparting velocity to a liquid. The velocity is converted into pressure and flow by the casing.

Centrifugal pumps must be combined with a driver into a centrifugal pumping unit in order to be useful. Centrifugal pumping units vary in complexity from the simplest and most common – an end-suction pump close-coupled to an electric motor – to complex custom-engineered multi-million dollar units that consist of many individual components.