What is Specific Speed (Ns)?

Specific speed, or Ns, is an index of impeller design that describes the relationship between the amount of head generated by the rotation of an impeller relative to the amount of flow produced by the impeller.

The formal definition of specific speed, or Ns, according to Cameron Hydraulic Data is:

The speed at which an impeller, geometrically similar to the one under consideration, would run if it were reduced in size to deliver one GPM at one foot TDH.

However, the basic idea is that specific speed is a number used to describe the design of an impeller:

- Impellers that generate a lot of head, but very little flow have very low specific speeds.

- Impellers that generate very little head but a great deal of flow have very high specific speeds.

Specific speed is calculated on the basis of flow and head at BEP according to the following formula courtesy of Wikipedia:

![]()

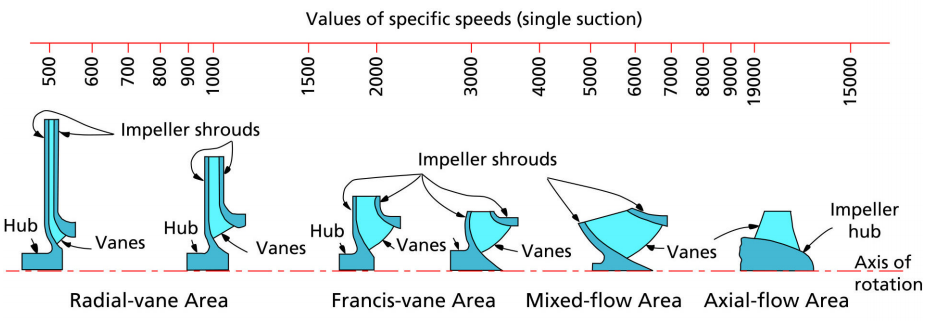

Common specific speed values for rotodynamic pump impellers fall between 400 and 15000.

Courtesy of Pump Fundamentals. Originally by the Hydraulic Institute

Specific speed can also be used to predict and evaluate pump efficiency and the shape of the pump performance curve.

- Higher specific speeds are associated with higher efficiency pumps with efficiency falling dramatically for designs with specific values below 1000.

- As specific speed increases, BEP tends to skew farther and farther towards the end of the pump curve.

- As specific speed increases, BHP at shutoff tends to rise.

- As specific speed incresaes, head at shutoff tends to rise relative to head within the AOR.

Jacques Chaurette’s excellent article Centrifugal Pump Specific Speed Primer and the Affinity Laws provides a great deal more detail on this topic.